OBJECTIVES DRIVEN ENGINEERING

ENGINEERING PRODUCTS THAT OUTSMART COMPETITION - RIGHT FIRST TIME

It not only takes high quality and clear differentiation for new products to excel in today's competitive market. Manufacturing companies should also 'get is right first time' to maximize product profitability. The pressure to develop better products faster is therefore continuously increasing.

Manufacturers can no longer afford not to use virtual prototyping in their product development process, if they want to stay in the running altogether. Leading the market and picking up the habit of timely developing benchmark products, requires them to go one step further and adopt an Engineer by Objectives strategy. A key enabler of this approach is the use of technologies as found in our products Optimus and id8 that maximally leverage engineering investments.

OUR TECHNOLOGIES ENABLE AN OBJECTIVES DRIVEN ENGINEERING STRATEGY

Engineering Workflow Automation

Engineering workflow automation enables engineering teams to set up and run engineering simulation campaigns in a structured way. Engineering simulation workflows generally link up a series of both commercial and in-house developed applications, formalizing simulation best practices into a well-documented and repeatable process.

Design Space Exploration

Building on formalized engineering workflows, our Design Space Exploration technologies allow engineering teams to judge up-front what is realistic in terms of achievable product performance and required development duration – altogether eliminating the need for an iterative trial-and-error engineering approach.

Engineering Data Analytics

Huge amounts of engineering data are being generated while exploring the design space and optimizing product designs. Our effective Engineering Data Analytics technologies help engineering teams gain deeper insights and visualize the design space in a limited time window, to ultimately help them make informed decisions.

THEY BRING SUBSTANTIAL BENEFITS TO ENGINEERING TEAMS

A faster & better engineering process

A formalized engineering workflow allows our software to act as a 'simulation robot'. It automates and directs simulations without any user intervention.

In capturing simulation know-how, manufacturing companies build up an information base of best practices. This enables them to standardize on superior development processes across the entire enterprise.

Empowering your experience

Design of Experiments (DOE) results explain the relative importance of design parameters and real-life constraints. This is based on a minimum set of well-chosen experiments.

Surrogate models condense simulations based on a set of virtual experiments defined by a DOE method. They are extremely effective in evaluating new designs. Not requiring any further detailed analyses, they help you quickly explore the entire design space and optimize product performance.

Delivering benchmark products

Our software solutions successfully tackle our customers’ industrial challenges. They enable them to make smarter moves toward products that excel in highly competitive markets.

By focusing on key product performances, state-of-the-art optimization methods open up remarkable development opportunities. They turn product challenges into differentiators that further increase customer satisfaction and business profit.

WANT TO KNOW MORE ABOUT HOW OBJECTIVES DRIVEN ENGINEERING CAN HELP YOU DEVELOP BETTER PRODUCTS FASTER?

Download our white paper »Industry-leading users of our solutions report design time savings averaging over 30%, while achieving 10% or more design performance improvements.

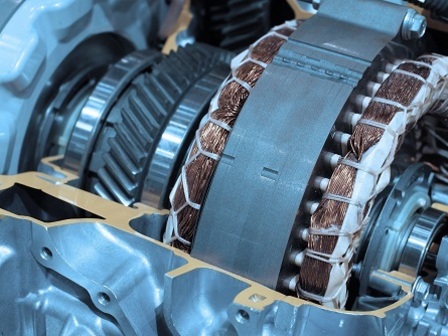

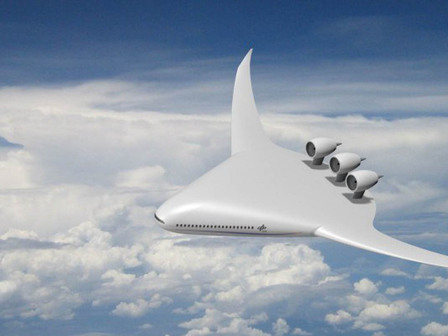

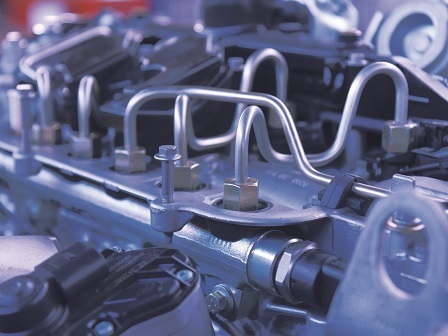

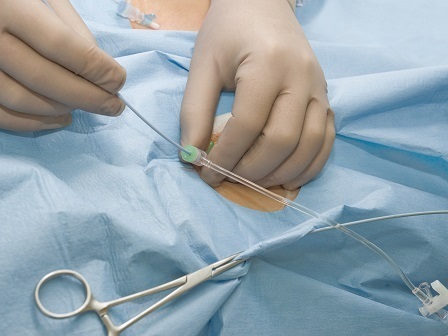

DISCOVER OUR INDUSTRY SOLUTIONS

Refine your search by selecting one of the engineering disciplines below

©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy