Tolerance Optimization Balancing Optical Performances

A case study on how to use Optimus to automate engineering processes and explore the capabilities of product designs

Data-driven product development strategy using Optimus

Multi-objective Optimization

Structural variations are inevitable in the manufacturing process and can only be minimized to a certain extent. In the development of lens tubes for cameras, strict specifications are imposed for the tolerance of the individual components to guarantee a predefined quality level. The aim while optimizing the design of lenses are to find a proper definition of the tolerances such that a certain optical quality reached.

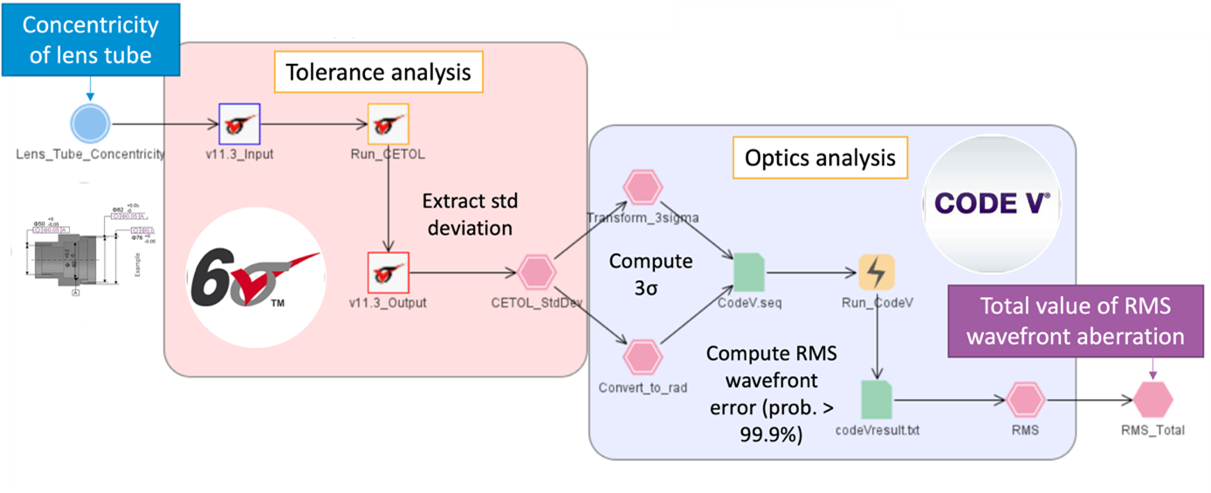

Measuring the optical quality of a lens tube

Many evaluation parameters can be used to measure the optical performance of a camera system. The Root-Mean-Square (RMS) wavefront aberration is an averaged error measure that describes the gap between the ideal wave front and the actual wavefront. It can be determined from the position and tilt of all lenses in a lens tube.

To find out more, download your free copy!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy