RELIABILITY-BASED OPTIMIZATION

DELIVERING A HIGHER DEGREE OF CONFIDENCE

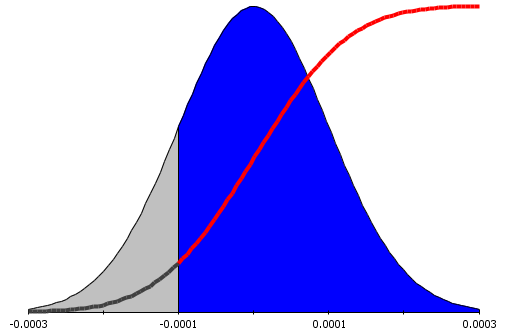

Reliability analysis assesses the probability that structures may fail for accidental combinations of low resistance and high loads – or, more generally, the probability that rare or extreme design conditions yield catastrophic consequences. Reliability analysis is critical across a wide range of industries, aerospace being a typical example.

Quantifying reliability of a design

Building on existing engineering workflows and adding statistical dispersion to the design parameters, reliability analysis aims to assess to what extent a design yields high output value consistency, stability and uniformity during repeated observation under the same conditions. Failure probability and reliability index are used to quantify the reliability of a design. The lower the failure probability or the higher the reliability index, the more reliable a design is.

Optimizing reliability of a design

Reliability-based Design Optimization (RBDO) uses the mean values of the random system parameters as design variables, and optimizes the objective function subject to predefined probabilistic constraints (such as failure probability or reliability index). As a result, an RBDO solution not only provides an improved design, but also a higher degree of confidence in the design.

Our RBDO technologies cover many different procedures using either limit-state approximations (such as FORM and SORM approximation methods) or sampling procedures (such as Monte Carlo Simulation, Line Sampling and Subset Simulation) to deliver solutions that work for various types of reliability problems.

EASILY DEPLOY ANY ENGINEERING METHOD

Discover how »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy