Engineering Optimization

RESOLVING MULTIDISCIPLINARY ENGINEERING CHALLENGES

Quickly identifying the optimum designs

In the process of engineering new products, development teams typically face conflicting design objectives for which they need to find an acceptable trade-off. They also need to take into account any design constraints imposed by manufacturing realities and more stringent regulatory and standardization requirements.

Automated search for optimum designs

For a long time, this has been done in an iterative way. Optimus however enables engineering teams to perform an automated coordinated search to identify the optimum design parameter values. This approach of tracing design candidates that best match performance objectives and respect design constraints, is not just significantly faster than any iterative process. It also delivers results that outperform competitive products.

With Optimus we were able to deliver an optimized EV motor design in a limited time frame – increasing efficiency and range autonomy. I-Wei Lan, Researcher at ITRI (Taiwan)

ITRI in Taiwan – A Thomson Reuters Top 100 Global Innovator - pumped up overall electric vehicle efficiency by 4 % using Optimus

Read the case study »Resolving even the toughest challenges

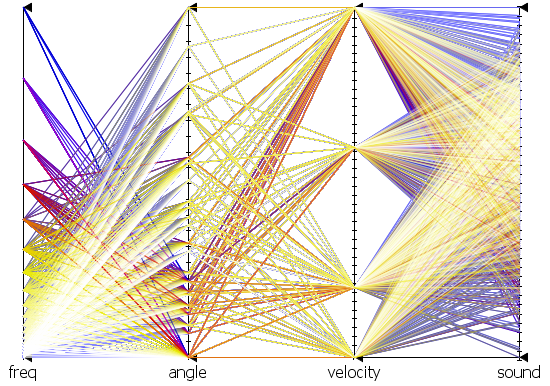

Optimus’ advanced numerical optimization algorithms easily resolve even the toughest multi-disciplinary multi-objective optimization challenges. Throughout the optimization process, Optimus informs engineers on the ongoing optimization progress and allow them to steer the process based on their extensive experience.

Regardless of product complexity, Optimus design optimization searches and finds those design candidates that outsmart competition. After a further evaluation of the proposed design candidates, development engineers can pick the most optimal design option and move on to the next stage of the development process.

Optimus is intensely used to engineer products that outsmart competition

Discover how »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy