Foster collaboration in your engineering design process

Case Study: A multi-disciplinary design optimization of a car’s crash box in a collaborative environment

Data-led Collaborative Engineering with id8

Collaborative Engineering

Impact and crash events occur very often in daily life and when it comes to cars, customers prefer to purchase a safe vehicle. In a vehicle, the crash box, an integral component for ensuring the safety of a car, serves as an energy-absorbing member, together with the bumper beam in case of frontal collision during car accidents. Collaboration is essential while designing and testing a crash box, as it involves multiple disciplines and areas of expertise of often siloed teams. Collaboration plays a key role in utilizing best-in-practice engineering workflows, conducting simulation analysis, sharing results to make data-led decisions, and fostering innovation in the organization.

Data-led engineering decisions

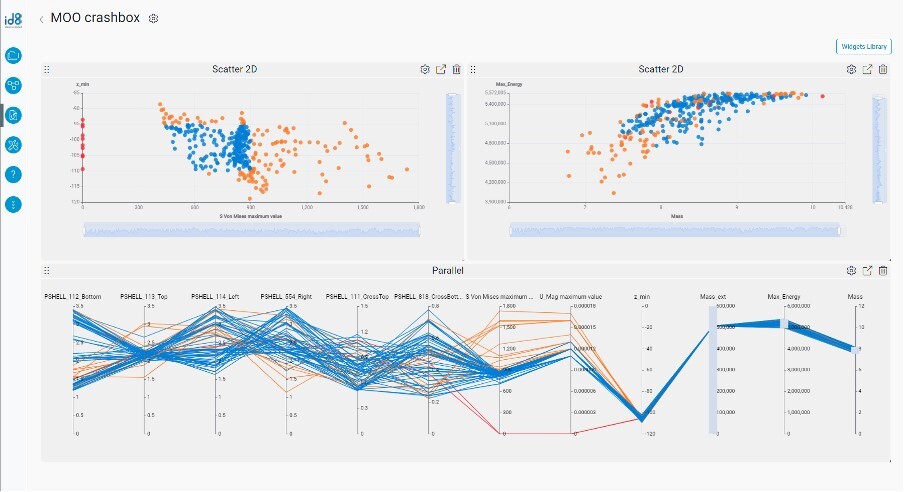

The id8 platform efficiently manages the hardware resources. Based on flexible configurations, id8 can distribute the simulation execution to hardware that is in the company’s (private) cloud or in local HPCs in the company’s domain. Once the simulations from different exploration and optimization strategies are completed, analysts can use the dynamic data analytics module of id8, analyze their data in interactive dashboards and create trustworthy insights, thereby increasing productivity and reducing time-to-design the crashbox.

To find out more, download your free copy!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy