Pushing fuel efficiency

A free application note on how Optimus steers multi-domain system simulation towards optimized hybrid electric vehicle design

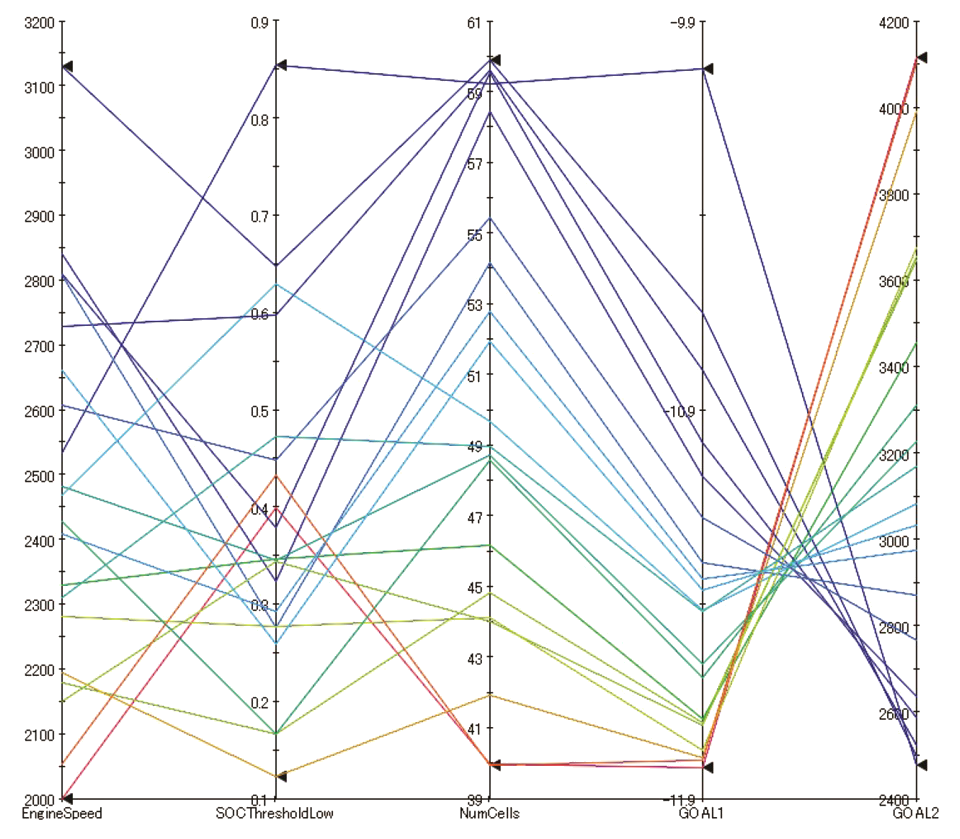

Optimus automates the traditional ‘guess & correct’ simulation-based design process, and with powerful optimization algorithms efficiently directs the system simulation campaign to identify the best HEV configurations. Through Optimus’ capabilities for Design of Experiments (DOE), Response Surface Modeling (RSM) and Multi-objective Optimization (MOO), engineers improved fuel efficiency by 21% and traveling performance (legal emissions compliance) by 15%. With MapleSim mastering HEV modeling and Optimus controlling simulation workflow execution, design optimization only lasted two weeks.

The challenge

The challenge for HEV development engineers is to obtain extreme fuel efficiency while complying with exhaust emission legislation. Authorities grant compliance for a specific HEV system type when the system's exhaust emissions are within the tolerated test cycle emissions window. The traveling performance - the difference between the actual and the legally defined emission levels - needs to be minimized to a certain extent to ensure robust legal compliance with emissions regulations.

Solution approach

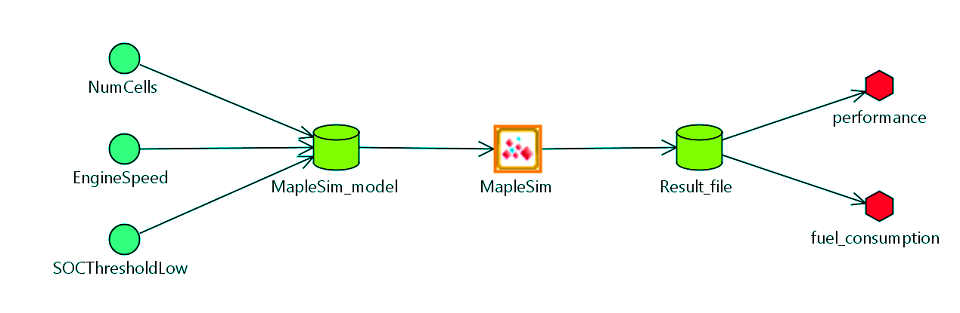

Engineers automated the MapleSim simulation process by sketching the process flow in Optimus' graphic drag-and-drop editor, quickly establishing a parametric connection with MapleSim without requiring any programming skills at all. Optimus was then used to automate and direct HEV development such that engineers were able to push fuel efficiency while still maintain the desired success rate with regard to emissions compliance.This ultimately deliverd an optimized HEV design that is 21% more fuel efficient and has a 15% better traveling performance compared to the initial design.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy