Optimizing Bus Construction Using Mixed Metals

A case study using Optimus, an automation and optimization tool by Noesis Solutions

Automate your entire simulation process with Optimus and reduce long simulation hours

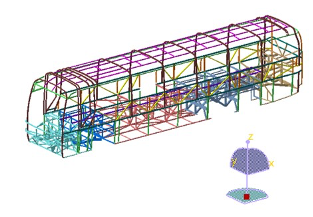

In the ever-evolving world of transportation, bus construction is undergoing significant advancements to enhance safety, efficiency, and sustainability. One notable development in the industry is the utilization of a mix of mild and high-strength steel in bus manufacturing, to meet the growing demands for fuel efficiency and safety. Optimizing this simulation process enables access to the weight-saving potentials of bus body structures.

Using Optimus, the entire simulation process can be automated, and different design studies or intelligent optimization algorithms can be applied. The cost factor for the high-strength material can easily be changed and an appropriate design can be selected according to the desired saving of mass and cost.

This case study presents a machine-learning algorithm that addresses the challenge by guiding numerical experiments at different fidelity levels, adaptively selecting sampling locations, and optimizing the design using Optimus.

To find out more, download your free copy!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy