Optimus Interfaces

LS-DYNA

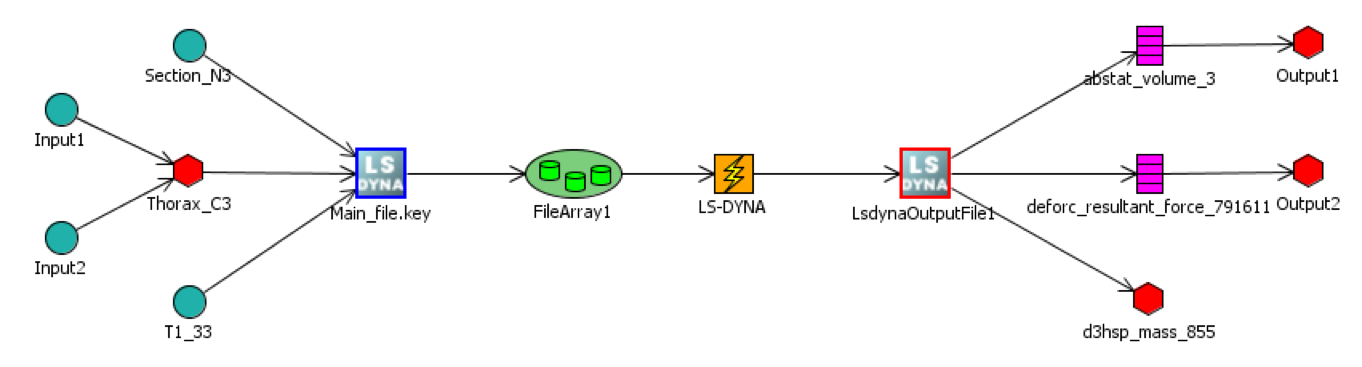

The direct interface for LS-DYNA supports the efficient optimization of engineering challenges involving nonlinear transient dynamic finite element analysis. It automates the creation of an engineering workflow that contains LS-DYNA model entries. A powerful embedded search engine offers dedicated filters, to simplify the selection of design parameters and result components from the model based on LS-DYNA card and key names, user identifier and names, output file type and desired result components – allowing for an effortless parameterization. Include files statements, result files directories and selected parameters are automatically treated.

Orchestrating simulation campaigns

Optimus orchestrates parametric simulation campaigns involving LS-DYNA, freeing users from repetitive manual model changes and data processing. Using Optimus’ Design of Experiments (DOE), Response Surface Modeling (RSM) and Numerical Optimization methods, engineering teams quickly identify product designs that meet a combination of objectives set by multiple (often competing) performance targets. At the same time, design constraints imposed by manufacturing realities or stringent regulatory and standardization requirements are consistently taken into account.

Integration in a few clicks

Optimus automatically modifies the LS-DYNA design parameters, updates the underlying models and extracts the result outputs (scalar and vectors) in an automated simulation or optimization process. Built on Optimus’ User Customizable Interface (UCI) wrapper technology, the Optimus interface for LS-DYNA allows to access all advanced parameters and versions of LS-DYNA without any configuration programming - enabling the parameterization and workflow integration of any LS-DYNA model with just a few clicks.

DISCOVER OUR INDUSTRY SOLUTIONS FOR LS-DYNA

WANT TO KNOW HOW OUR SOLUTIONS CAN HELP YOU DEVELOP BETTER PRODUCTS FASTER WITH LS-DYNA?

Get in touch »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy