CRASHING SAFELY

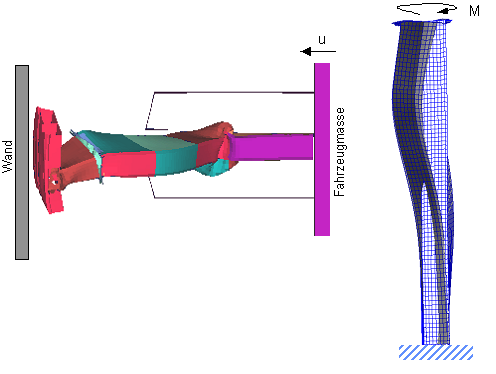

A free application not presenting the optimization of an aluminum frame side rail in terms of front crash behavior

An aluminum frame side rail has requirements in terms of front crash behavior, but also in terms of static behavior. This application note shows how Optimus is used to optimize the design of the side rail. Optimus captures the workflow (including both the static and the crash analysis), automates simulation software execution, explores the design space and identifies the optimal design variables.

Simulation facts

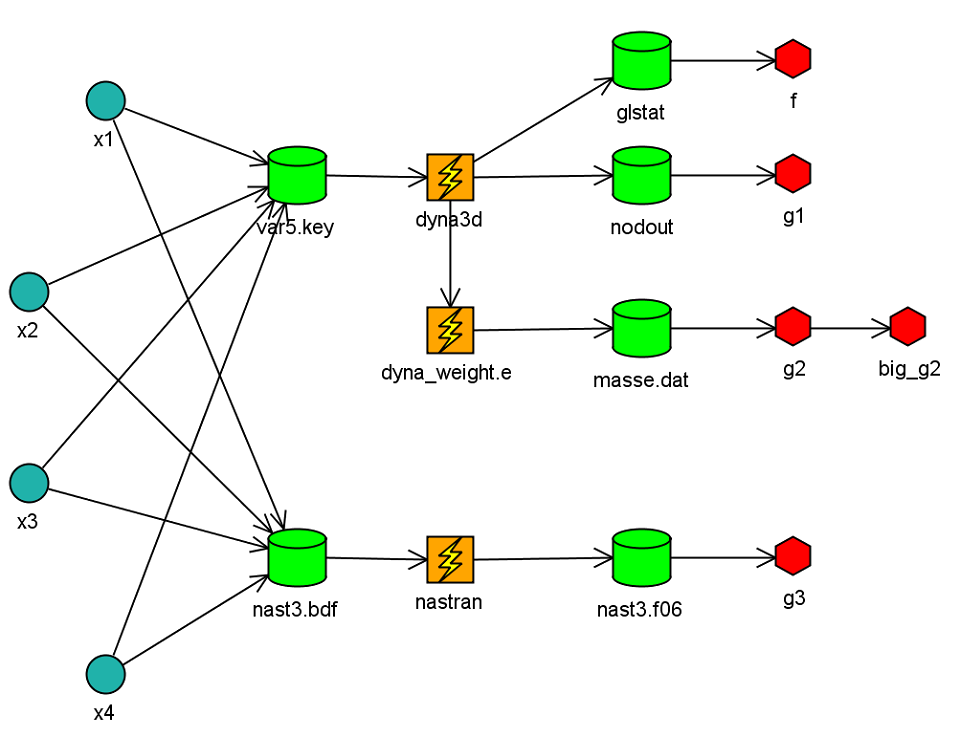

Front crash behavior of the aluminum frame side rail is modeled with the explicit finite element code LS-DYNA, while its static behavior is modeled with MSC Nastran. Optimus is then used to build an engineering workflow that not just allows to predict the behavior of the frame side rail, but that is also capable of delivering a design that meets the required performance criteria.

Solution approach

The engineering workflow captured by Optimus includes LS-DYNA and MSC Nastran, as well as all related input and output files. From the automatically generated parameter list, the engineer easily selects the input parameters and responses that are needed for optimization purposes. That optimization is focusing on maximizing the inertial energy absorbed during the front crash, while taking into account a number of critical constraints.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy