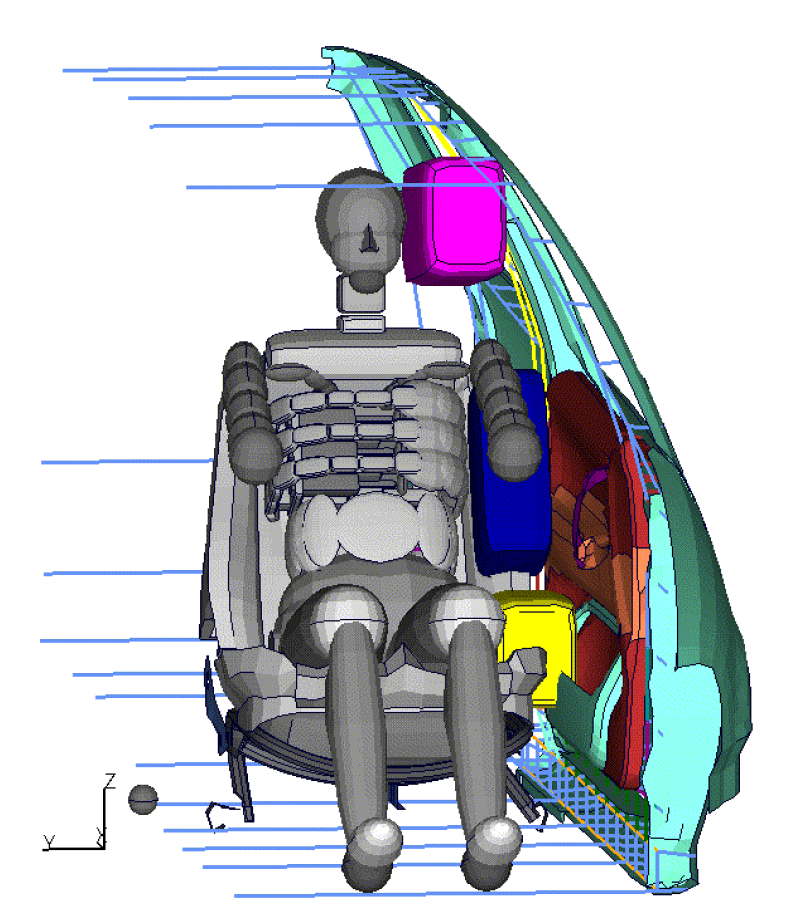

Side Protection

A free application note that discusses the optimal design of a vehicle airbag through investigation of the influence of side airbag stiffness on dummy load in a side struck vehicle

In automotive crash design, dummy loads have to be as low as possible while the structure is able to withstand the limiting values of the safety criteria imposed by the authorities. This application note shows how Optimus is used to investigate the influence of the side airbag sitffness on the dummy load in a side struck vehicle during a 90-degree vehicle side impact. Optimus captures the engineering workflow, automates software execution, explores the entire design space and identifies the optimal design variables.

Simulation facts

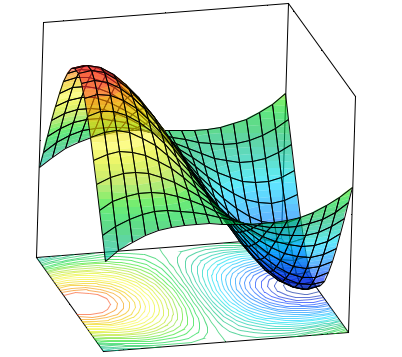

Traditionally, the crash analysis of an impact has been an open-ended approach. Given a certain design, crash analysis software calculates stresses, margins of safety and energies. But these analyses don't necessarily deliver a design that meets the required performance criteria. To provide deeper insights into the overall behavior of the engineering model and to identify designs that meet or even exceed specifications, design space exploration techniques are needed.

Solution approach

The engineering workflow, including both PAM-CRASH and MADYMO, is easily captured using the Optimus graphical user interface. Input parameters and responses, as needed for design space exploration & optimization purposes, are captured by the engineering team from the automatically generated parameter list. Optimus Design of Experiments and Surrogate Modeling techniques are then used to explore the entire design space - ultimately reducing the dummy load by 13% while keeping the safety criteria well below the maximum allowed values.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2024 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy