A day in the life of Lucas

A deep dive into our diverse & open-minded workforce

An internship is your first step towards your career goal. It teaches you responsibilities and the realities of a real job. Lucas Ponton, a Materials Engineering student from Polytech Marseille was actively looking for roles in aeronautical and automotive space, when he found an opportunity with us. Lucas was interning with Noesis Solutions for 3 months as an Engineering Intern at Leuven. The goal of his project was to help one of Noesis customers to improve their plastic injection process. He worked on linking Optimus with Molding Injection Simulation software, Moldex3D.

What excited you the most about the internship?

It was the project that was assigned for me. It helped me gain not only technical knowledge, but also in project management and people management. They trusted me with the project and gave me a lot of responsibilities. It enhanced my knowledge in material engineering, CAE (computer-aided engineering) and industry processes. I learnt more in my internship than I expected to.

How does an ideal day at Noesis look like for you?

Early birds get the worm. Not just that, they might also get sometime for sightseeing later in the evening. At Noesis, we have flexi-hours. So, I was able to decide my own schedule. I like to come to work early, do my research and prepare for the day early. There are a few other early birds like me, we get breakfast together from the fridge and some coffee before starting my day. I experiment on Optimus software to achieve my goals for the internship. It is a flat organization, so if I have any doubts, I just send them a message on Teams, and everyone is always ready to help.

Tell us more about the project that you were assigned?

I am extremely interested in the automotive and aeronautical industry. That is one of the key reasons why I wanted to work with Noesis Solutions. In my internship, I linked Optimus software with Molding Injection Simulation software, Moldex3D. With this, we aim to reduce the time and costs for our customers by automating their performance and manufacturability analysis. This will tell them how the manufacturing parameters will impact the end results before the start of production.

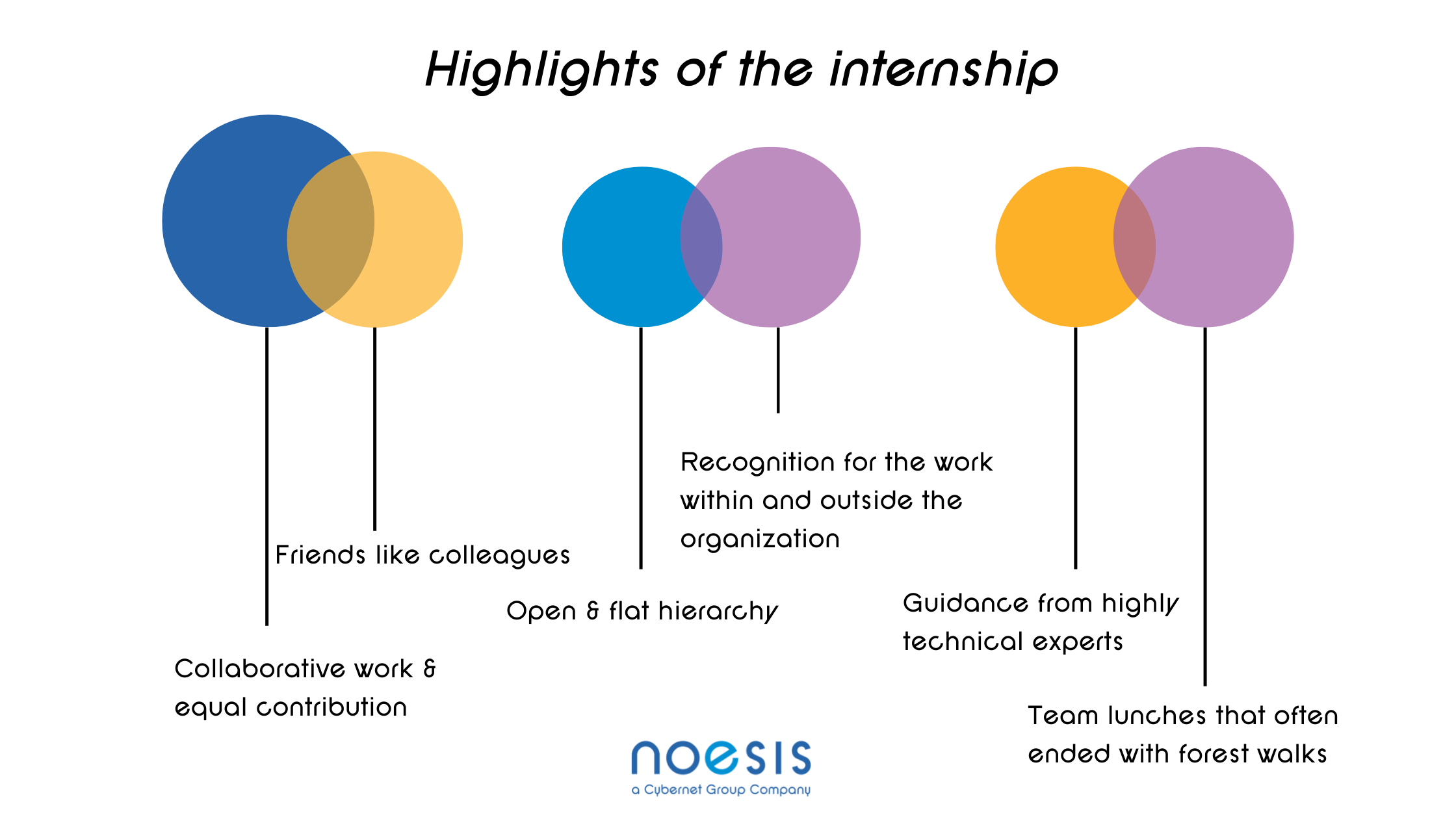

What was the highlight of your internship?

Apart from the knowledge and practical experience, I loved the work environment. They were all like my friends. We usually went for a walk in the nearby ‘forest’ after lunch, it was a wonderful way to unwind and brainstorm innovative ideas. Once during the walks, it was a nice and sunny weather, and suddenly it rained heavily. We were all completely drenched and laughed so much. That was my first experience of Belgium weather.

YOU HAVE A QUESTION FOR US?

Get in touch »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy