Automation of plastic injection molding

An on-demand webinar to understand the advantages of automation of plastic injection simulation

Injection molding is a crucial process in manufacturing industry, from aeronautical components to automotive parts to a simple water bottle. Automation of the plastic injection simulations during the development phase of a product can save considerable costs resources and, most importantly, time. Even in the initial phase of a project, professional simulation solutions help to determine the manufacturability of specific designs. For a plastic manufacturer, these precise data will reduce the correction loops significantly.

In this ‘Automation of plastic injection molding’ webinar, along with Moldex3D, a leading CAE (Computer Aided Engineering) product for the plastic injection molding industry, we will go through -

- Running plastic injection simulations automatically

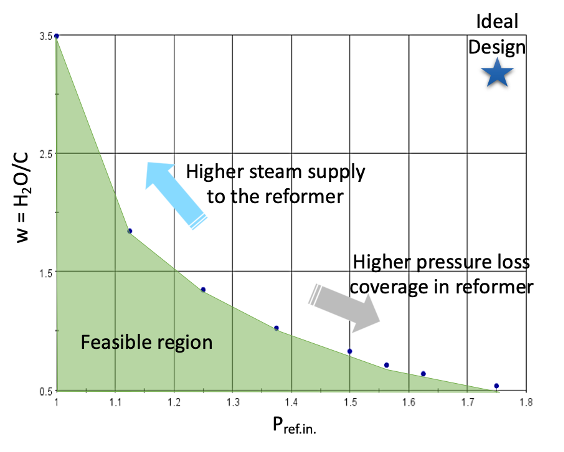

- Discovering the ideal plastic injection parameters to produce a plastic component for NOVARES, global plastic solutions provider

- Deriving the best result based on customized criteria

- Driving multiple Moldex3D simulations on Optimus, industry-leading Process Integration and Design Optimization (PIDO) software platform

Speakers

- Sophie Petraman, Application Engineer, Noesis Solutions

- Wilson Chien, Account Manager, Moldex3D

©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy