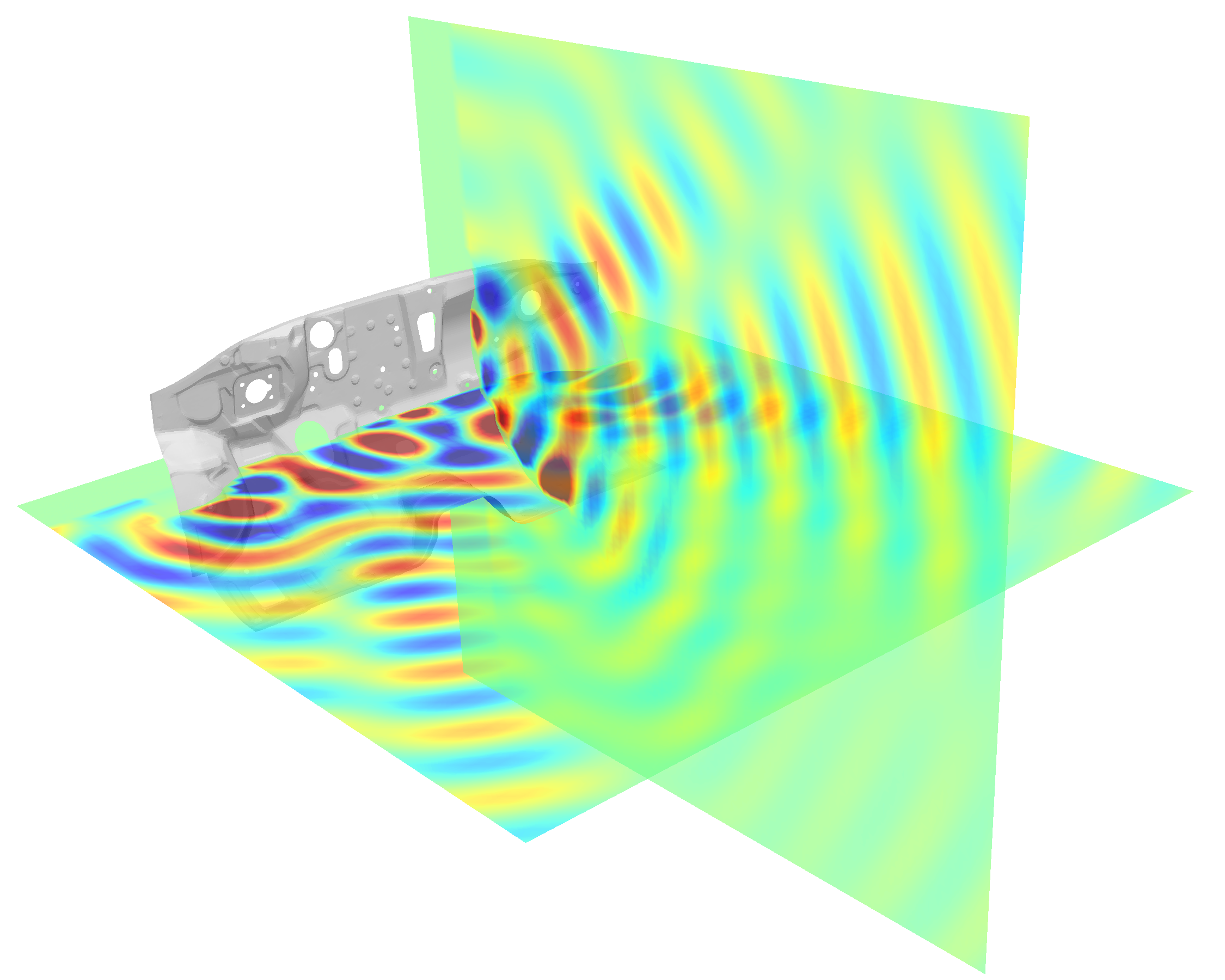

Acoustic optimization of an engine compartment panel

Combining Optimus with Actran material modeling - An 60 minutes webinar on demand

Acoustic comfort is one of the key elements of a pleasant and comfortable travel experience. For truck drivers, it is even a matter of health and productivity as high noise levels or unpleasant sounds in a working environment are known to cause excessive fatigue and health problems. Isolating the driver and passengers from annoying engine noise not just makes them feel much more comfortable, they will also feel less fatigued after a long drive. Providing outstanding acoustic comfort and performance requires the vehicle manufacturer to go through a complex design process, ensuring that noise transmission through the engine compartment panel is minimized while satisfying a wide range of design constraints.

Learn how to solve this optimization problem

Starting from a panel geometry of which the shape and configuration have been determined (including the position of holes for fixation of the steering column or air conditioning, …), the development team needs to identify the best trim layer configuration to attenuate the sound waves from the engine compartment. Each trim layer has his own thickness that may vary along the panel, while acoustic properties may also be non-uniform because of the complex material structure. The need to minimize the total mass of the panel and the impact of manufacturing tolerances adds additional complexity, making the acoustic optimization of an engine compartment panel one of the hardest nonlinear optimization problems to solve.

During this webinar, we will show you:

- How Actran material modeling technology can be combined with Optimus to automate any Actran-based simulation workflow,

- How to explore the design space to gain deeper insights into the key design parameters and the optimization potential, and to identify feasible panel designs,

- How to find the best trim layer configuration that maximizes acoustic performance of an engine compartment panel while satisfying all design constraints.

Looking for more in-depth information?

Actran is used to set up an acoustic model of the engine compartment panel, to evaluate noise transmission for any specific set of design parameters.

Optimus is used to set up an automated simulation process, driving Actran to deliver simulation results for any choice of design parameters – without manual intervention.

Optimus is used to conduct Design of Experiments, allowing for the use of highly effective strategies to execute virtual experiments at a minimum simulation cost.

Surrogate models are built and validated - giving confidence that these models are well suited to perform ultra-fast engineering optimization.

Powerful optimization algorithms deliver a trim layer configuration that maximizes acoustic performance while satisfying all design constraints.

Thanks to a wide range of different visualization technologies, the development team gets actionable insights and relevant decision metrics that maximize engineering productivity.

Find out much more

Watch now »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy