Shaping the flow

A free application note on how to use Optimus with ANSYS CFX for shape optimization of an axial-flow turbine nozzle

Shape optimization of an axial flow turbine nozzle typically requires significant manual engineering effort. For each design iteration, the engineer defines a new geometry, updates the mesh, executes the analysis and extracts the required outputs. This manual process can be easily automated with the help of Optimus. After capturing the analysis workflow in Optimus, the user explores the entire design space and automatically improves the design using single and multi-objective optimization algorithms.

Simulation facts

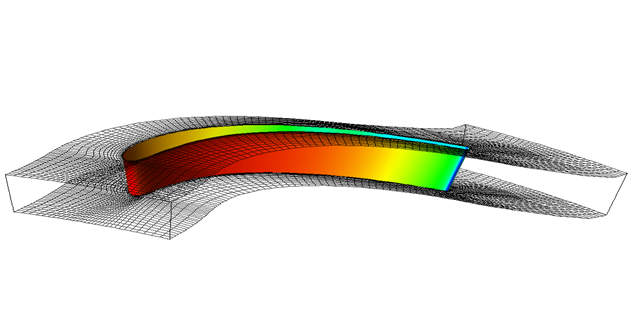

The aerodynamic behavior of an axial-flow turbine nozzle is analyzed with the ANSYS CFX fluid dynamics software. For a single experiment, 5 separate CFX modules (BladeGen for geometry, TurboGrid for meshing,CFX-Pre for pre-processing, CFX solver for computational fluid simulation and CFX-Post for post-processing) are used.

Solution approach

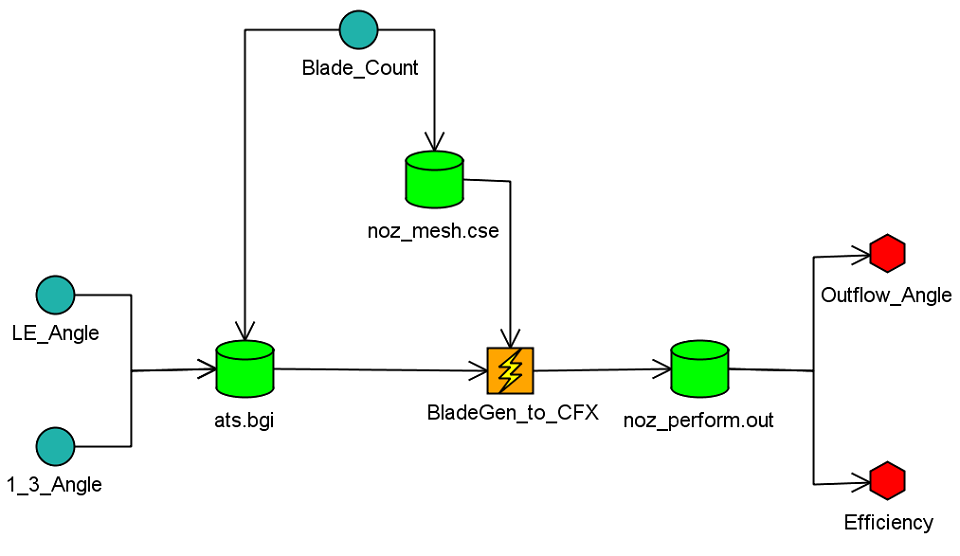

The engine performance simulation workflow is captured using the Optimus graphical user interface. This workflow includes the CFX software, as well as the related input and output files. The engineer selects the input parameters and responses which are required for optimization, from the automatically generated parameter list. Optimus parameterizes the input file and parses the output file for the desired combination of output parameters, allowing for an automated execution of the simulation workflow.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy