Making it last

A free application note that documents how engineers at the Fiat Research Center have used innovative approaches and technologies to significantly reduce the weight of an automotive suspension arm

Engineers at the Fiat Research Center have used innovative approaches and technologies to significantly reduce the weight of an automotive suspension arm. The objective was to automatically minimize the weight of the control arm by changes to its geometry - within the design constraints of a given fatigue lifetime and impact strength.

Simulation facts

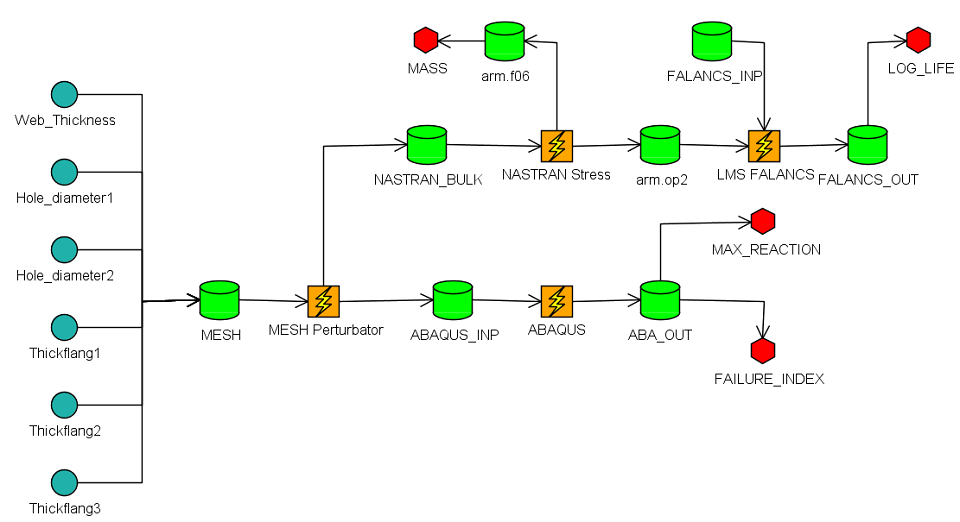

Suspension systems are designed by an iterative process in which engineering simulation is used to evaluate each design alternative.Fiat Research Center engineers used multibody simulation software, with actual road load information as input, to develop subsystem loads that reflect true operating conditions. Optimus was then used to explore the full range of design alternatives for the suspension component.

Solution approach

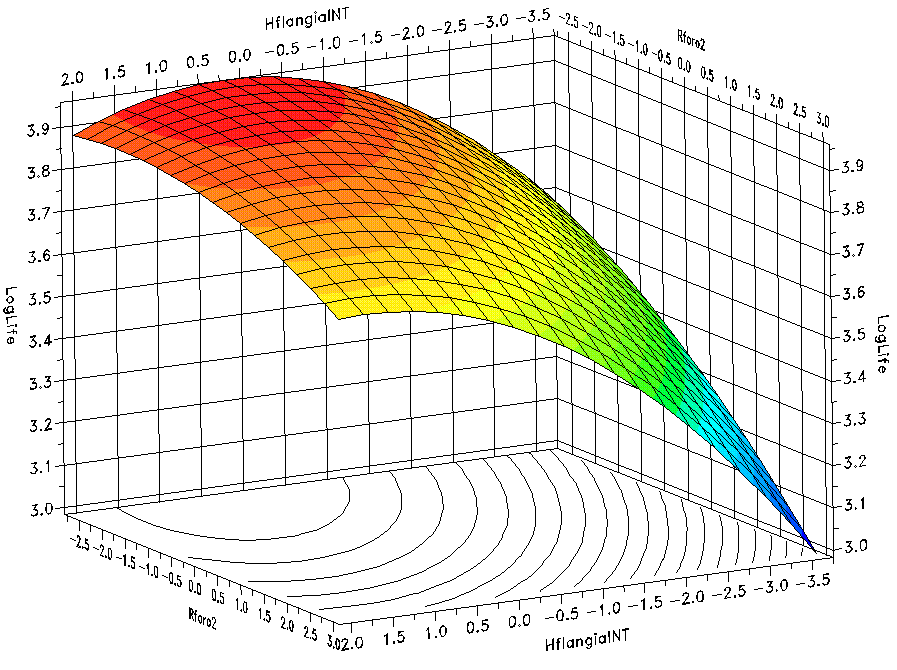

Using Optimus to parameterize the model of the suspension arm, engineers can easily investigate the effect of various design parameters on structural response and fatigue lifetime. In doing so, Optimus automates any repetitive tasks that are required to prepare the models (saving a lot of valuable engineering time) and entirely eliminates the traditional trial-and-error approach to research alternative designs. Using state-of-the-art optimization methods, Optimus delivers a design that ensures a mass reduction of 8% while satisfying all performance constraints.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy