Keeping Cool

A free application note on how to optimize CPU cooling inside laptops

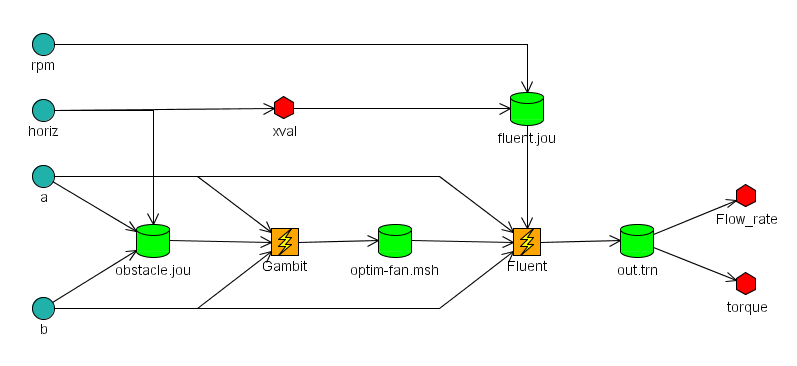

ANSYS Fluent efficiently and accurately predicts the air flow and temperatures inside a laptop. This application note shows how Optimus automates this CFD analysis process, and modifies the design to maximize the air flow rate while avoiding peak temperatures inside the enclosure. Optimus builds the simulation workflow, automates software execution, lets the engineer explore the entire design space, and determines the optimal location and size of the active heat sink as well as the optimal fin spacing of this heat sink.

The problem

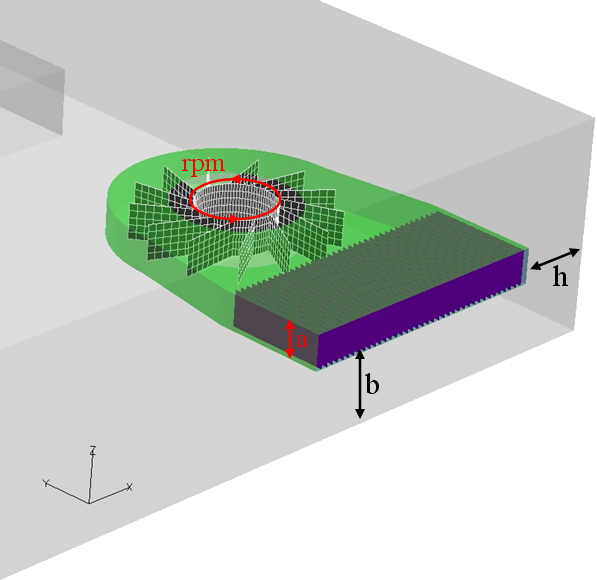

With increasing clock speeds, CPU cooling has become a major concern of processor manufacturers, especially for portable computers. Within a laptop, the location, height and the fan speed of an active heat sink greatly influences the amount of air it is capable to deliver as well as the amount of heat it dissipates for a given amount of consumed electricity. Uniformity of the flow through the fins is also very challenging in order to avoid local temperature peaks and CPU breakdown.

Solution approach

By parameterizing the geometry and cavity mesh of the laptop, engineers can investigate the effect of various design parameters on air flow rate and heat dissipation. The entire simulation workflow is therefor captured using the Optimus graphical user interface, and then serves as the basis for a Design of Experiments simulation campaign which generates a data set to which Optimus fits mathematical response surface models to build so-called surrogate models. Those surrogate models help the engineer to better understand and estimate the effect of the design inputs on the flow rate and the torque.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy