Identifying foam properties

A free application note which documents a parameter identification problem on a foam material

This application note documents a parameter identification problem on a foam material. It shows how the engineering optimization algorithms implemented in Optimus are used to identify foam material properties that fit the available experimental results. Optimus captures the engineering workflow that is needed to calibrate modal properties, drives the engineering software and finally delivers the optimal material characteristics.

Simulation facts

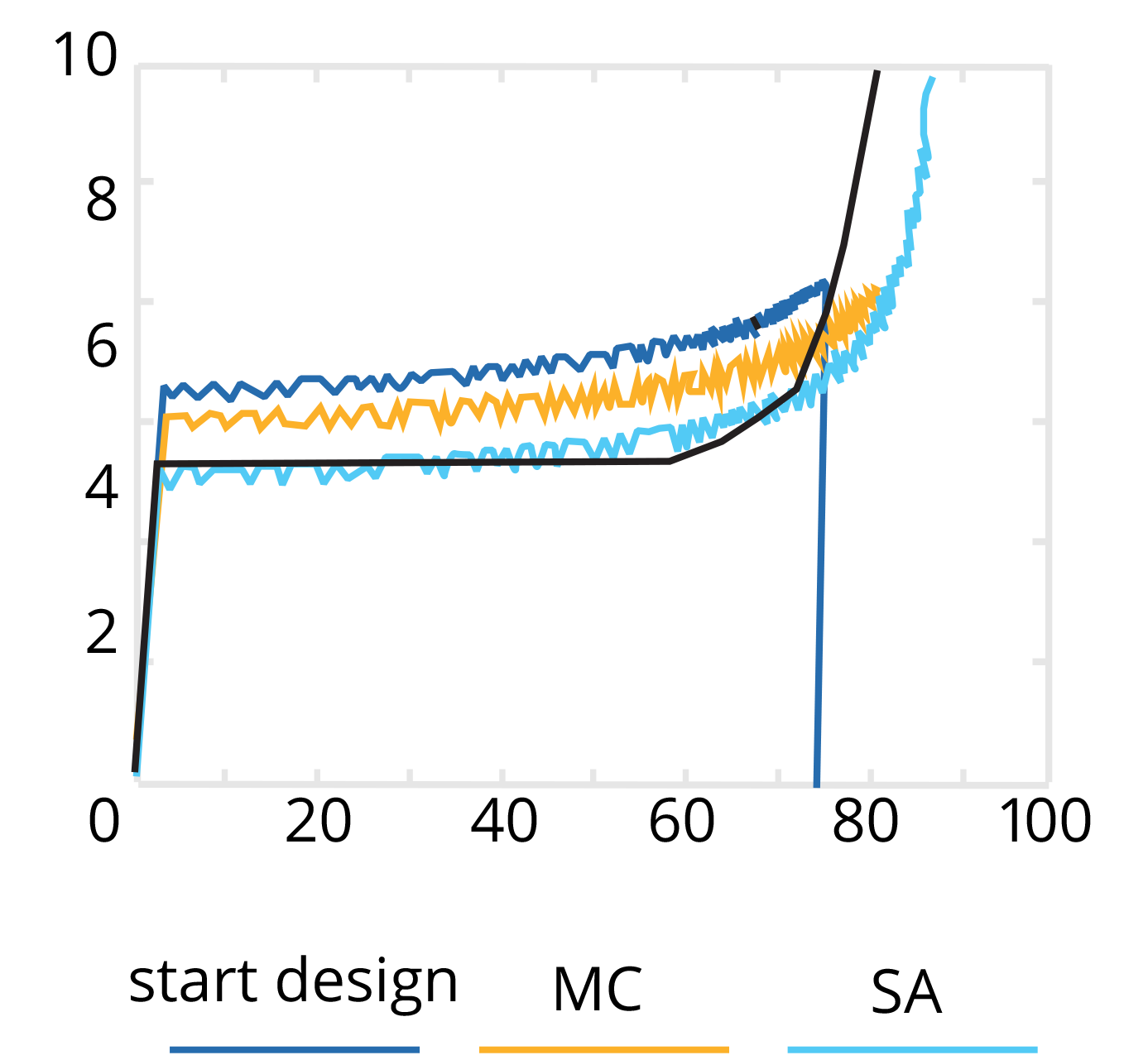

Traditionally, parameter identification on (foam) materials using available experimental data has been an open-ended approach. Given a certain set of material parameters, an analysis delivers force-displacement curves but doesn't necessarily guarantee that calculated material characteristics match available experimental data. Optimus is therefore needed for provide deeper insight into this calibration problem and to identify material characteristics that provide good correlation with available test data.

Solution approach

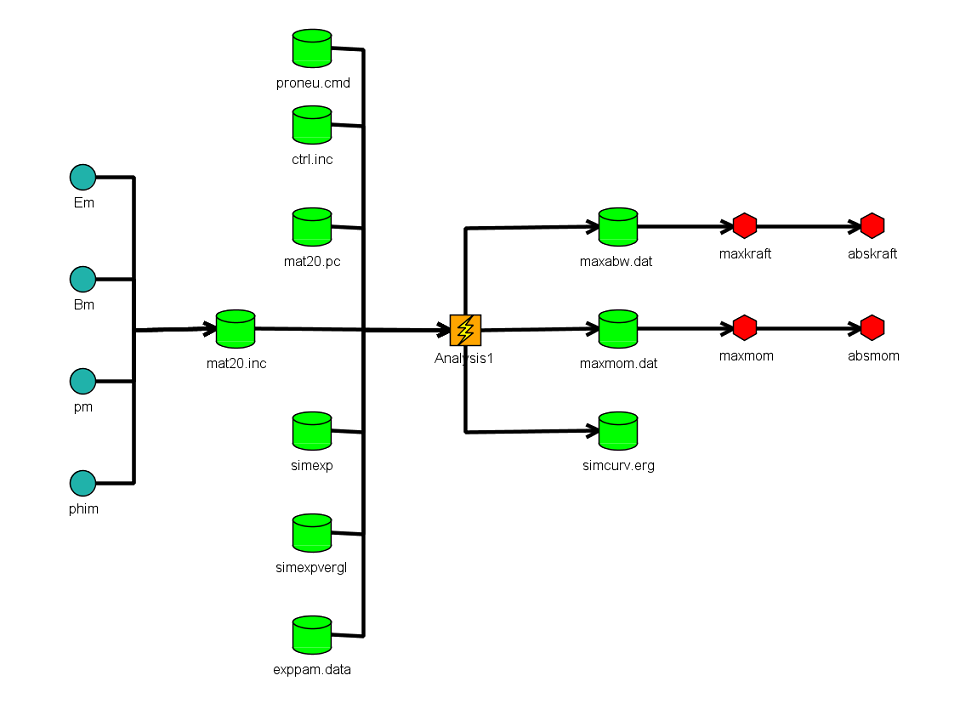

Experimental data on the foam material is obtained by dropping a mass on a foam cube. This experiment is also modeled and analyzed using PAM-CRASH. Deformations of the foam cube are compared with the previously obtained experimental data. The engineering workflow that is needed to calibrate material model properties with these experimental data is captures using Optimus. Optimus then automates the execution of the workflow, and ultimately minimizes the difference between the force-displacement curve that is based on test data and the force-displacement curve delivered by the PAM-CRASH simulations.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy