Drawing deep

A free application note discussing the optimization & robustness analysis of deep drawing parts

Deep drawing parts are analyzed using finite element codes to predict and improve buckling behavior before a prototype is built. This application note shows how Optimus is used with PAM-STAMP 2G and Abaqus to identify sensitivity of the buckling behavior to the input parameter variation and to improve the robustness of the buckling behavior.

Simulation facts

Deep drawing simulation can typically be used for validation purposes only. If the objective is to maximize the robustness of buckling behavior, Optimus is needed to evaluate design sensitivities and to explore the entire design space. This provides deeper engineering insights and makes it possible to identify designs that meet or even exceed engineering specifications.

Solution approach

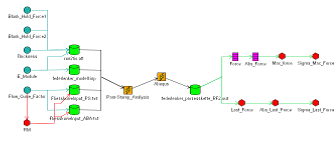

The engineering simulation workflow, including PAM-STAMP 2G and Abaqus, is captured with Optimus. From the automatically generated parameter list, engineers select the input parameters and responses that are required for optimization.Combining Design of Experiments, Surrogate Modeling and Robust Optimization technologies, Optimus finds an optimal design that delivers a 19% decrease in the sensitivity of the final buckling force to the variation of the noise parameters.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy