Calibrating solenoid models

A free application note highlighting how Optimus is used with LMS Imagine.Lab AMESim to modify geometry and spring characteristics of a solenoid model to match available test data on solenoid behavior.

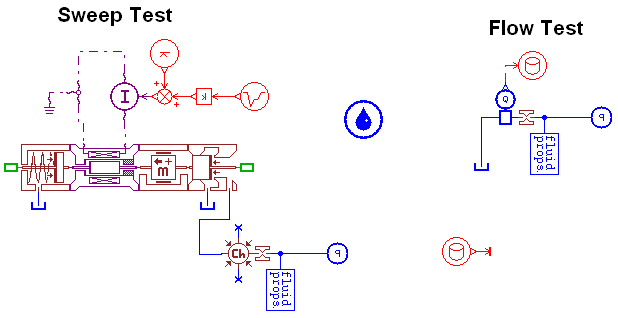

In engine transmissions, variable bleed solenoid valves are analyzed to predict their mechanical, hydraulic, magnetic and electronic behavior. This application shows how Optimus is used with LMS Imagine.Lab AMESim to modify geometry and spring characteristics to match available test data, to predict parameter sensitivities and to determine design parameter impact on solenoid behavior.

Simulation facts

In order to obtain the desired pressure vs. electric current behavior of variable bleed solenoid valves, the orifice diameter, minimum air gap, seat diameter, valve stroke and spring preload of the valve are optimized to reach the desired target curve with its characteristic hysteretic behavior. Where-as simulation is typically used to validate designs, Optimus is needed to investigate the sensitivity of the design due to parameter changes and the envelope of the performance curves due to parameter variability.

Solution approach

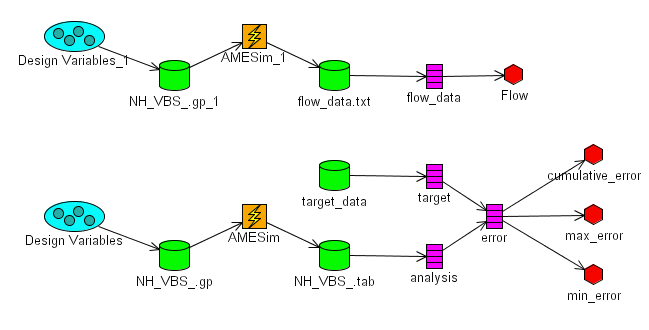

The simulation workflow is captured using the Optimus graphical user interface. This workflow includes the AmeSIM software, as well as the related input and output files. The engineer selects the input parameters and responses which are required for optimization, from the automatically generated parameter list. Optimus parameterizes the input file and parses the output file for the desired combination of output parameters, allowing for an automated execution of the simulation workflow.

TO FIND OUT MORE, DOWNLOAD YOUR COPY!

Download your copy »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy