WORKFLOW INTEGRATION TECHNOLOGIES

EASILY PARAMETERIZING ANY WORKFLOW

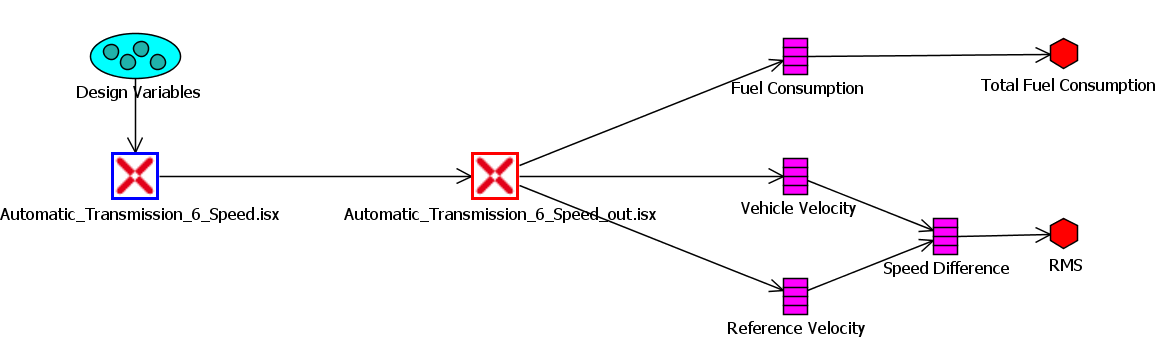

Parameterizing an engineering workflow only takes minutes using our flexible and open workflow integration technologies, and requires no programming skills whatsoever. Simple drag-and-drop actions help define inputs and outputs that need to be considered as design parameters, engineering objectives or constraints.

Direct drivers and interfaces

Direct drivers and interfaces are available for a broad range of engineering software programs. The extensive list covers – among others - tools such as LMS Virtual.Lab, LMS Imagine.Lab Amesim, Microsoft Excel, Abaqus, Adams, ANSYS Workbench, AVL Workspace, BETA ANSA, CATIA V5, FloMASTER, LS-DYNA, MapleSim, MATLAB, MSC Nastran, PTC Creo Parametric, RICARDO Wave, Siemens NX CAD & CAE, SimulationX, STAR-CCM+, etc.

Each pre-programmed interface manages the parameterization of the underlying engineering model without requiring the user to deal with any complex file syntax, substitutes design parameters, and extracts simulation results. Automatically launching and running the various engineering simulation tools is achieved by embedding direct drivers in the engineering workflow, without the need for any user programming.

Generic drivers and interfaces

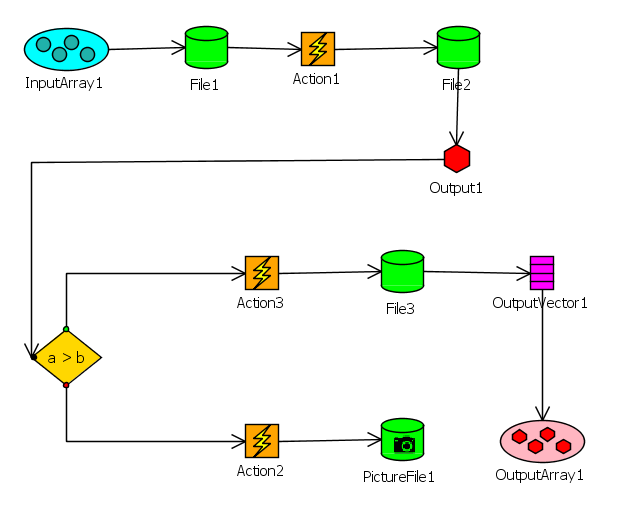

In case no direct driver or interface is available for a specific engineering software program, integration can be easily achieved through our generic input file parameterization and generic output file parsing mechanisms. They can be used to flexibly embed any software into even the most complex types of engineering workflows. Generic parameterization allows for defining any input parameter as a design variable, while our generic parsing mechanisms extract both scalar and vector values from any output file. Both mechanisms require that the user has a sound knowledge of the underlying file syntax.

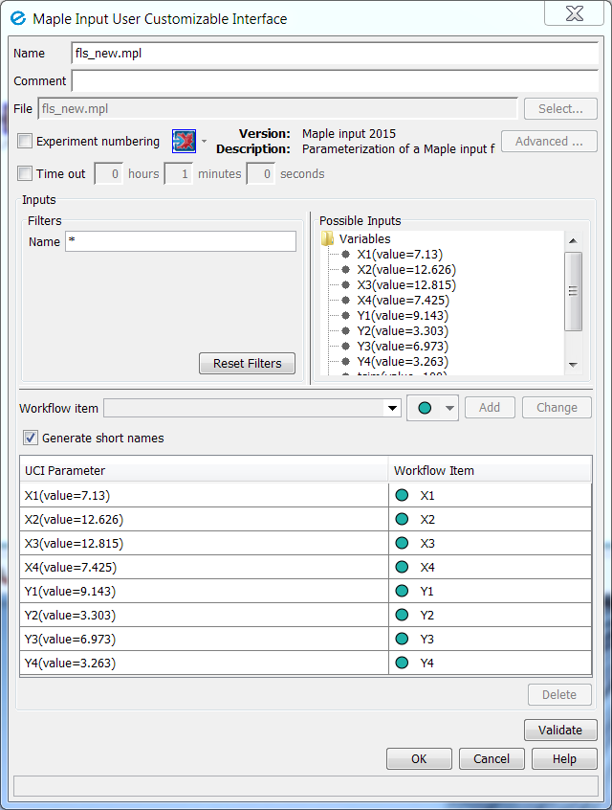

User-customizable interfaces

The syntax-related complexity is entirely removed through our user-customizable interfaces (UCI). These allow engineers to easily capture and wrap any commercial or in-house simulation software into an engineering workflow. Accessing design parameters and simulation results is realized through a pre-programmed dialog window that removes the need to have specialized knowledge about the underlying file syntax. Substitution and extraction of design parameters and results rely on the same unique wrapper technology.

UCIs for dedicated software programs can be stored locally, or can be made available at a central location for reuse by peers. As a consequence, it is just as easy to include a UCI in a specific engineering workflow as with any of our standard interfaces. User-customizable interfaces support both ASCII and binary file formats.

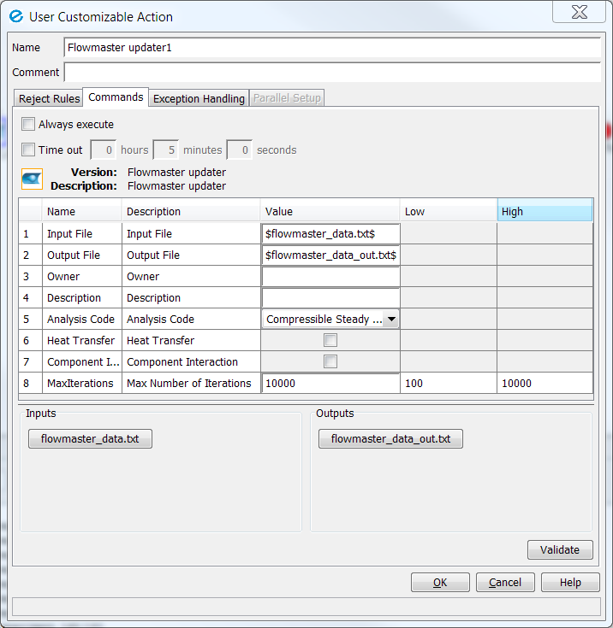

User- customizable actions

User-customizable actions (UCA) on the other hand, are dedicated XML-based templates that wrap all knowledge required to launch engineering simulations and to process any script-related interventions through an easy-to-use dialog window. The details related to each simulation software (platform dependency details, executable path, resource management system scripts, version management, or default parameter values) are stored in a central location and can be shared with other users without any further modification. That makes it extremely easy to embed UCA’s within any engineering workflow.

READY TO DISCOVER THE BENEFITS OF OPTIMUS ENGINEERING PROCESS INTEGRATION?

Read more »©2024 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy