Accelerate automotive crashworthiness with AI

Accelerate automotive crashworthiness with AI

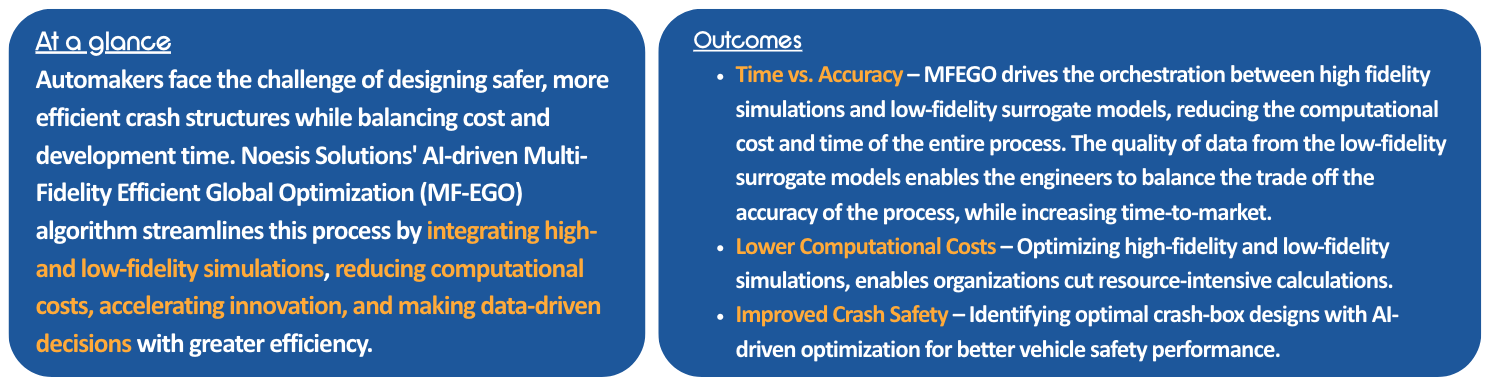

Discover how Noesis Solutions helps automakers optimize crashworthiness, cut costs, and accelerate design cycles with AI-driven MF-EGO optimization.

Crash analysis is always amongst the top priorities of improving vehicle safety and performance in an automotive industry. The evolution in the powertrain technology will not make crash analysis obsolete anytime soon, as the safety of the battery pack is introduced a new challenge to the manufacturers. Meanwhile, the historically existing crash analysis have the potential to be upcycled to gain knowledge in advance for the design of battery packs in Electric Vehicles (EV) chassis. However, Automakers face the ever-growing challenge of designing safer, more efficient crash structures while balancing cost and development time.

We spoke about this case study in detail with a demo in our recent webinar - Optimizing automotive crashworthiness with AI. If you missed it, click on to this link to watch the on-demand recording of it.

Challenges in the manual process

Running high-fidelity crash simulations for every design iteration is resource-intensive and expensive.

- Demanding optimization problems may end up in an excessive number of high-fidelity simulations, for which the time and resources cannot be justified.

- Each full-scale crash simulation can take hours or even days, delaying innovation and decision-making.

- This traditional iterative simulation cycles can promise high accuracy, but limits the exploration of design variants, due to time and cost constraints.

AI-driven Approach

Based on the challenges, and the constraints and parameters of a crashbox design, we developed a strategy to develop an engineering process, that tackles the time and cost constraints, while developing a competitive product. By leveraging a hybrid approach that combines high- and low-fidelity simulations, Noesis Solutions can enable automakers to achieve the same level of accuracy at a fraction of the cost and time that engineers would otherwise spend with traditional iterative approaches.

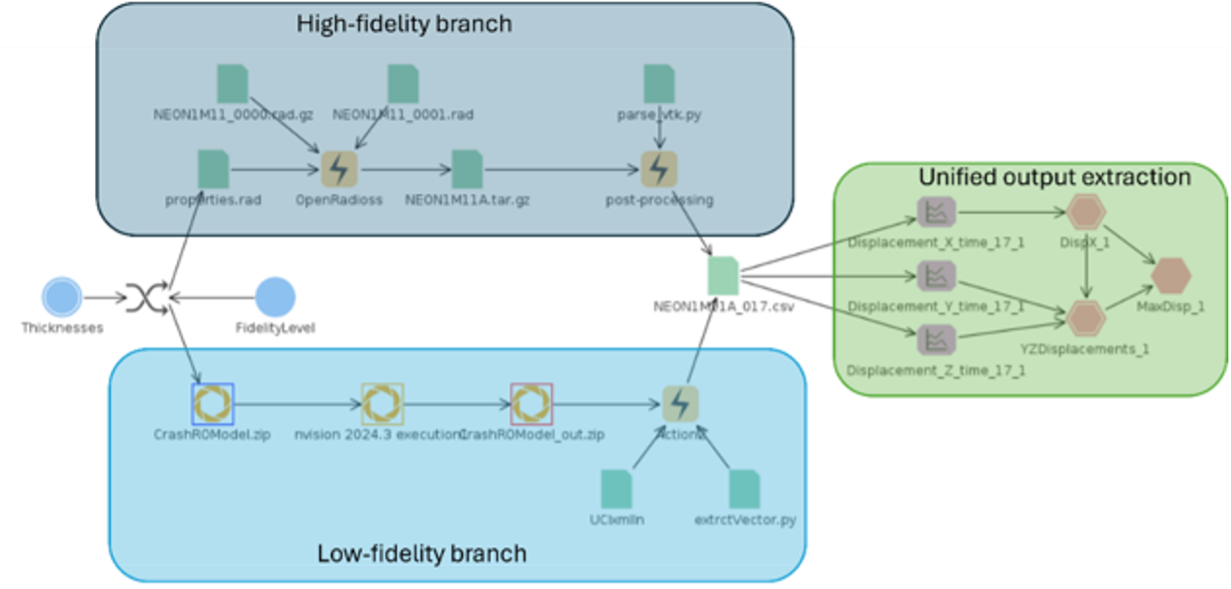

To address these challenges and the trade-off between simulation accuracy and computational efficiency, MF-EGO algorithm is used to orchestrate the usage of low-fidelity calculations in the form of surrogate models, developed using nvision, together with high-fidelity simulations. The goal here is to identify the optimum with reduced computational cost with respect to the Efficient Global Optimization (EGO).

Workflow Creation

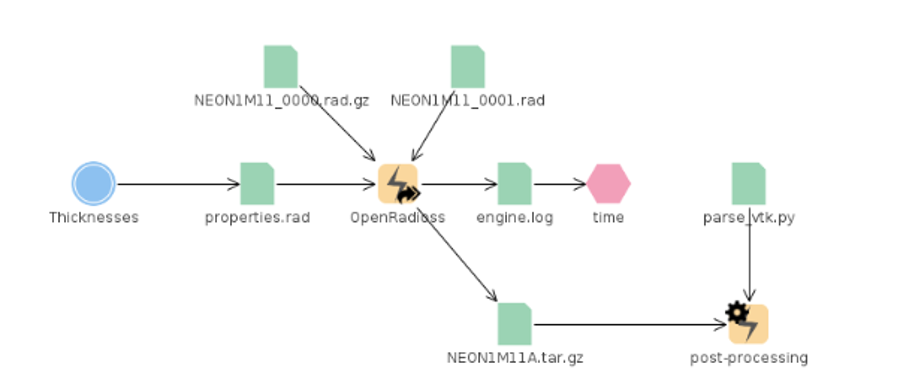

High-Fidelity Calculations: A car crash simulation (12.5 m/s impact) is run on AWS using OpenRadioss. Variables include bumper, rails, and fender thicknesses. This orchestration is managed by Optimus, as illustrated in the image below. A 50-sample Design of Experiments (DoE) provided 47 valid datasets, each with transient results at 17 time-steps, forming the training foundation for ROMs.

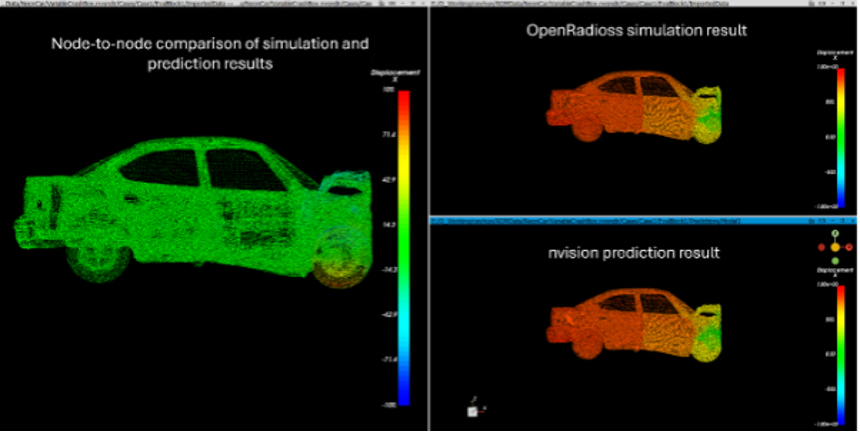

Low-Fidelity Model Training: Low-Fidelity surrogate models are built in https://www.noesissolutions.com/our-products/nvision. The overall training time of the surrogate models was about 4 hours, and prediction time for new datasets around 30 minutes. The surrogate model demonstrated average errors of 2 orders magnitude lower than the absolute nodal values. The 3-D visualization tool of nvision provides engineers a detailed look on the errors and their distribution in the simulation domain (image below). This high quality of the nvision model enables engineers to maintain the accuracy of the process.

An Optimus workflow coordinates both HF and LF branches. A switch dynamically chooses fidelity for each evaluation, guided by MF-EGO. The computational cost ratio favors LF predictions (0.08x compared to HF runs). Inputs and results are standardized for seamless comparison.

Technical Results

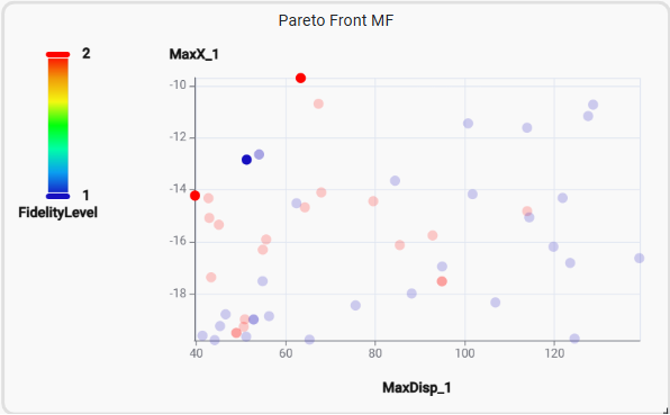

The good balance between high- and low-fidelity samples and more importantly, having both fidelity levels on the Pareto Front (Image below) indicates that the MF-EGO has driven the orchestration of resources with accuracy, reducing the computational cost of the entire process. This was possible thanks to the quality of the low-fidelity ROM trained with a representative HF database.

Measuring success

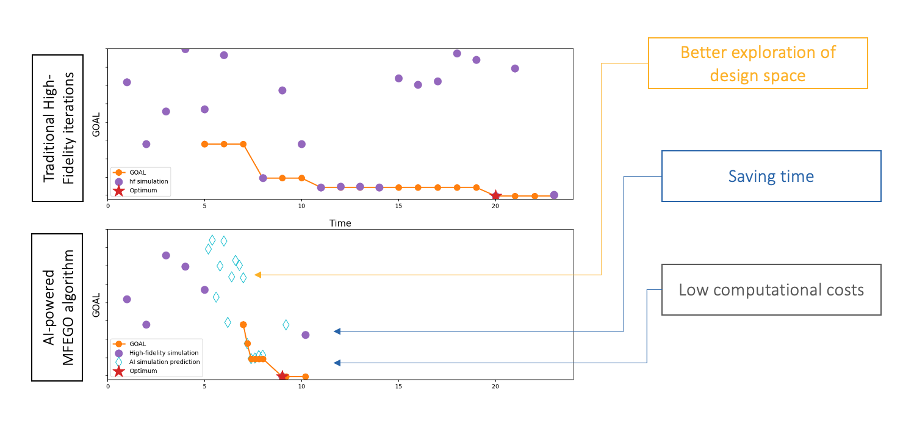

By leveraging Noesis Solutions’ AI-driven MF-EGO algorithm, the automaker successfully accelerated crash safety innovation, reduced computational costs, and improved collaboration across engineering teams (benchmark below). The combination of high- and low-fidelity simulations enabled faster, more efficient design iterations without sacrificing accuracy.

Tags

Other posts

-

What's new in Optimus 2025.1 — More Power, Control and Efficiency

May 19, 2025

-

R&D: The Centre of Innovation in Engineering

Apr 29, 2025

-

Bringing AI to Engineering Postprocessing: The Story Behind Optimus AI Postprocessing

Feb 26, 2025

-

Are siloed engineering teams draining your resources and slowing down innovation?

Feb 26, 2025

-

Are Engineers Ready to Fully Embrace AI Models in Design and Analysis?

Jan 27, 2025

©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy