Smart Design Space Exploration with new Optimus Adaptive DOE

A 60' on-demand webinar,

showcasing how Optimus Adaptive DOE

will get you better results with a lower budget

SAVE A LOT OF TIME, AND STILL GET THE BEST INFORMATION POSSIBLE

Understanding the behavior of your engineering simulation models is the first important step in setting up a deterministic or robust optimization project. Using Design of Experiments (DOE) early in the process, you can boost your productivity by planning your engineering simulations to deliver a maximum of relevant insights at minimum simulation cost

But when it comes to picking the right DOE strategy, things may become more complicated. Should I use a standard Min – Max approach, or should I choose a random strategy? Should I privilege space-filling techniques, at the risk of missing out on any non-linearities that may exist?

A FULLY AUTOMATED APPROACH THAT MAKES THE BEST USE OF YOUR SIMULATION BUDGET

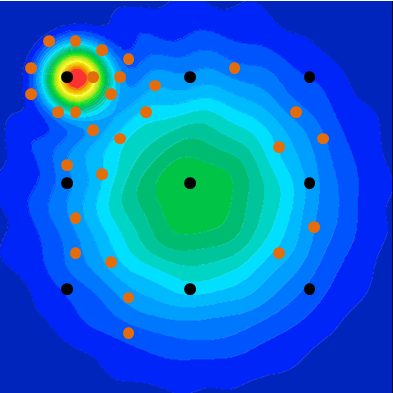

Optimus now offers a smart and fully automated approach that will make the best use of your simulation budget. The new Optimus Adaptive DOE algorithm will learn from the already available data points, and iteratively add extra data samples in design space regions that really matter. This will not just save you a lot of time, but will get you the best information that you can possibly get for your simulation budget.

Join to learn how

- you can address the issue of picking the best Design of Experiments technique without any preliminary knowledge on your model,

- Adaptive DOE will put you on the right track by facilitating initiation of an optimization algorithm or by feeding a surrogate model with the best possible training set,

- you can maximize ROI for your software and hardware investments thanks to Optimus’ smart parallel computing capabilities.

Looking for more in-depth information?

Optimus captures and automates any engineering simulation workflow - minimizing the computational footprint.

With a wide choice of preconfigured direct interfaces, including interfaces for ANSYS and CREO Parametric, setting up an engineering simulation workflow is easy.

Optimus is used to conduct Design of Experiments, allowing for the use of highly effective DOE strategies in combination with parallel execution strategies.

Optimus Adaptive DOE accumulates design space knowledge as the simulation process runs, adding DOE samples where needed most and removing the hurdles of any 'black box' DOE approach.

High-fidelity surrogate models, built on the representative set of virtual experiments obtained from the DOE campaign, then reveal valuable relationships between design parameters and performance metrics.

Multiobjective optimization algorithms deliver a set of Pareto-optimal solutions, among which the engineering team can choose the best fit.

Find out much more

REGISTER NOW »©2024 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy