DESIGN SPACE EXPLORATION

JUDGING UP-FRONT THE ACHIEVABLE PRODUCT PERFORMANCE

Eliminating TRIAL-AND-ERROR ENGINEERING

Building on formalized engineering workflows, Design Space Exploration technologies allow engineering teams to judge up-front what is realistic in terms of achievable product performance and required development duration – altogether eliminating the need for an iterative trial-and-error engineering approach.

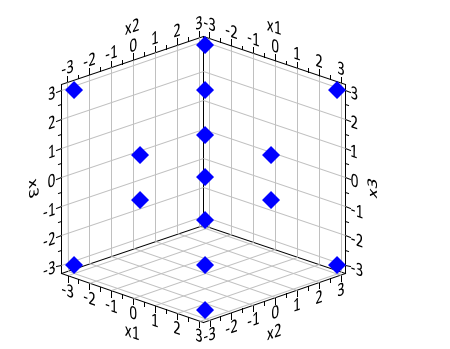

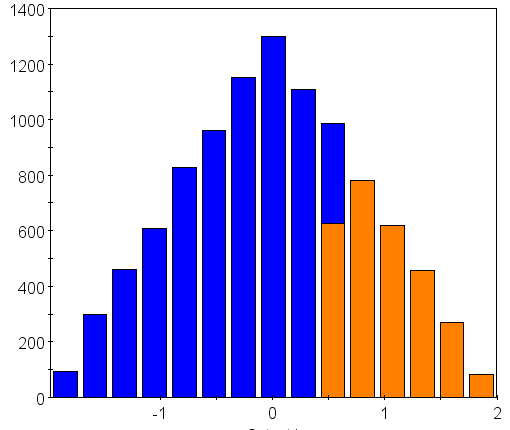

Design of Experiments

To enhance product performance and engineer products that outsmart competition, engineering teams require profound design space knowledge to help them fully understand the engineering potential. Design of Experiments (DOE) technologies allow them to efficiently sample the design space by defining and executing a set of optimally chosen virtual or physical prototyping experiments. Combined with our workflow automation technologies, DOE helps them save considerable amounts of time in the product development process.

Read more »

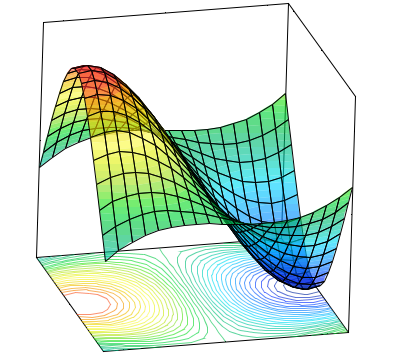

Response Surface Modeling

Response Surface Modeling (RSM) condenses complex engineering simulations into so-called surrogate models, using the results of virtual or physical prototyping experiments defined by DOE. It involves a collection of mathematical and statistical methods that help model and analyze problems in which a response of interest is impacted by several parameters. These models allow to evaluate new designs in seconds without requiring a full detailed engineering analysis, or to perform ultrafast design optimization.

Read more »

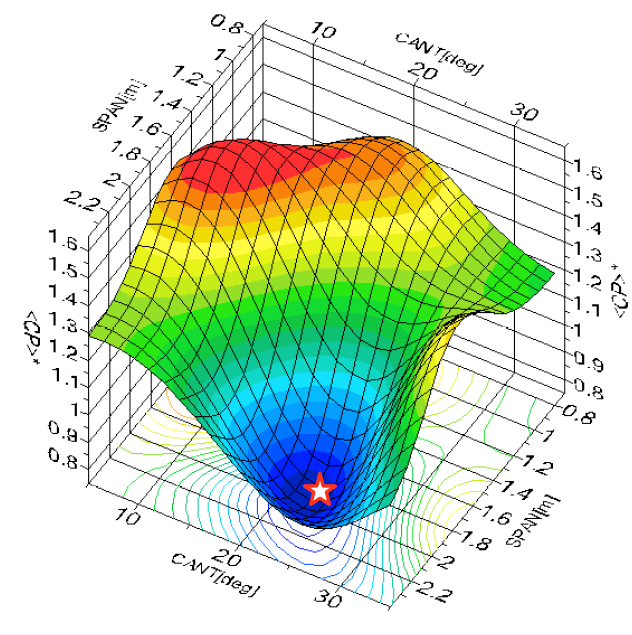

Numerical Optimization

Numerical optimization methods efficiently trace the extremes of a function, through an intelligent arrangement of evaluations. Traditionally, engineers start from an initial set of design parameters. When manually trying to improve the design, they judge the impact of these parameters on possibly conflicting engineering objectives, such as minimum weight, minimum cost and maximum product performance. With our engineering optimization technologies, that entire process is reversed – enabling engineering teams to work their way back from design targets to the most appropriate design parameter values.

Read more »

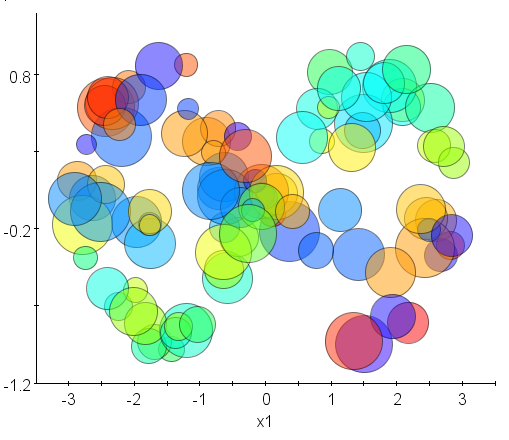

Multi-objective Optimization

Many engineering challenges require dealing with multiple objectives instead of a single objective. As some of the objectives may be (partially) conflicting, the design optimization effort becomes more complex. In most cases, specific trade-offs between certain criteria are required to work toward a satisfactory optimal design configuration. Multi-Objective Optimization (MOO) algorithms allow design optimization take into account multiple objectives simultaneously, with each objective targeting a minimization or a maximization of a specific output.

Read more »

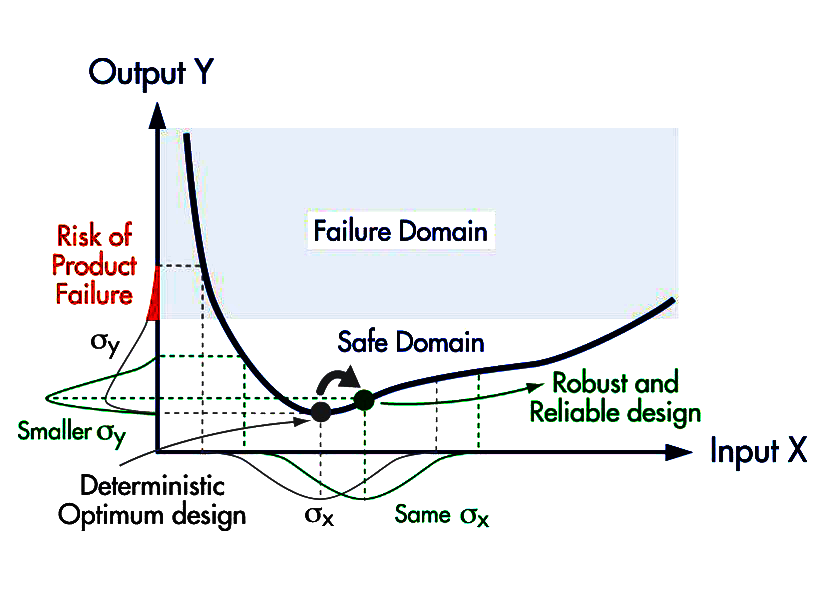

Robust Optimization

Engineering simulation is a typical example of a deterministic process. For a given set of input variables, the corresponding outputs are always identical. However this is not the case in the real world, where input variables may vary slightly as a result of manufacturing tolerances and geometric properties. To avoid that such variations negatively impact the expected product quality, Robust Optimization takes into account the variability of these design parameters and subsequently applies robustness concepts and methods to ensure a design continues to meet quality targets.

Read more »

Reliability-based Optimization

Reliability-based Optimization not only provides an improved design but also a higher degree of confidence in the design. It minimizes the probability that structures may fail for accidental combinations of low resistance and high loads – or, more generally, the probability that rare or extreme design conditions yield catastrophic consequences. Reliability is critical across a wide range of industries, aerospace being a typical example.

Read more »

Methods Integration Technologies

As part of our Design Space Exploration platforms, we offer framework tools to plug in any user-developed method. This enables engineering teams to build highly customized design space exploration methods based on in-house developed technologies, but also to consolidate the related IP in a comprehensive and industry-proven environment.

Read more »

SAMPLING THE DESIGN SPACE UP-FRONT

Discover how »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy