Optimus结合ANSYS Maxwell实现机电设备电磁优化设计 - 2017年8月25日

60分钟的网络研讨会重点介绍如何实现机电设备的电磁优化

SAVE A LOT OF TIME, AND STILL GET THE BEST INFORMATION POSSIBLE

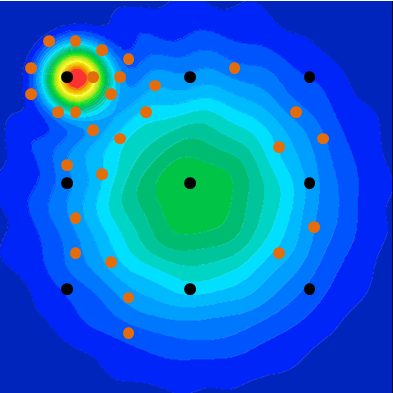

Understanding the behavior of your engineering simulation models is the first important step in setting up a deterministic or robust optimization project. Using Design of Experiments (DOE) early in the process, you can boost your productivity by planning your engineering simulations to deliver a maximum of relevant insights at minimum simulation cost

But when it comes to picking the right DOE strategy, things may become more complicated. Should I use a standard Min – Max approach, or should I choose a random strategy? Should I privilege space-filling techniques, at the risk of missing out on any non-linearities that may exist?

A FULLY AUTOMATED APPROACH THAT MAKES THE BEST USE OF YOUR SIMULATION BUDGET

Optimus now offers a smart and fully automated approach that will make the best use of your simulation budget. The new Optimus Adaptive DOE algorithm will learn from the already available data points, and iteratively add extra data samples in design space regions that really matter. This will not just save you a lot of time, but will get you the best information that you can possibly get for your simulation budget.

您能从本次网络研讨会中了解

- 如何使用Optimus对ANSYS Maxwell直接接口,方便地创建自动运行的仿真工作流。Optimus能自动识别仿真模型中的设计参数和计算结果,供用户方便地选择。

- 如何构建和验证在设计空间中建立准确的响应面模型,更方便地实现与其他专业的交互,并在更短的时间限制内实现的多目标优化。

- 如何使用工业级优化算法找到多个可行的最优设计,并使用设计决策工具找到满足不同专业要求最佳设计方案

- 如何探索设计空间,使用试验设计方法进行相关性分析,找到设计指标影响较大的关键设计因素。并且使用并行计算缩短计算时间。

了解更多相关信息

更多信息

报名本次网络研讨会 »©2025 Noesis Solutions • Use of this website is subject to our legal disclaimer

Cookie policy • Cookie Settings • Privacy Notice • Design & Development by Zenjoy